Iimveliso

I-18-8 / A2 I-HEX HEX yentsimbi ye-hex

Inkcazo

| Igama lemveliso | I-Stainess Steen Hex Amantongo |

| Izixhobo | Yenziwe ngentsimbi ye-18-8, la maqhosha anokuchasana nemichiza efanelekileyo kwaye unokuba ngumanyatha. Babizwa ngokuba yintsimbi engenasibala. |

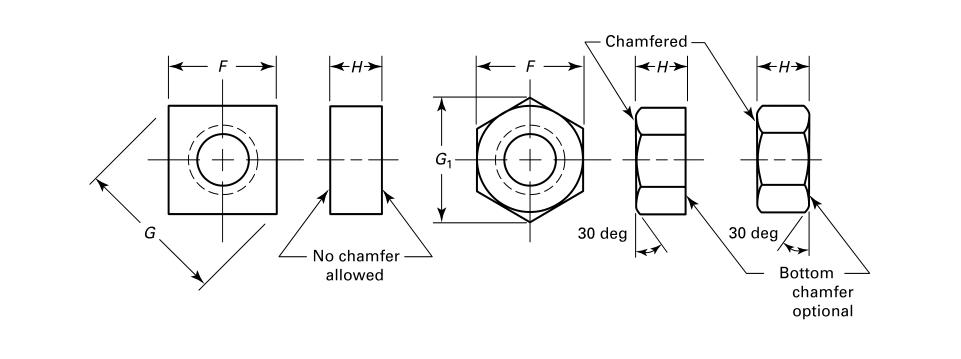

| Uhlobo lokuBumba | Hex nut. |

| Umgangatho | Amantongomane ahlangabezana ne-Asme B18.2.2 okanye i-Din 934 yeenkcazo zihambelana nale migangatho milinganiselo. |

| Inkxaso | La manyathelo afanelekileyo ukuba akhawuleze oomatshini kunye nezixhobo. |

isicelo

I-Stainess Hex Amantolone i-starveriners enendawo enamacala amathandathu, i-hexagonal yenzelwe ukuba isetyenziswe kunye neebhanti ukukhusela izinto ezimbini okanye ngaphezulu kunye. La maqhosha enziwe kwintsimbi engenasimo, ebonelela ngokuxhathisa inyibiliko, ebangela ukuba balungele uluhlu olubanzi lwezicelo, ngakumbi kwiindawo ezigcina amanzi, imichiza, okanye izinto zobuthathaka yinkxalabo. Nazi ezinye izicelo eziqhelekileyo ze-hex engenanto yentsimbi:

Ishishini lokwakha:

I-Hex Ext isetyenziselwa ukwakhiwa kwezinto ezibonakalayo ezakhiwo, ezinjengeebhulethi, iikholamu, kunye nokuxhasa, apho ukumelana nokuchasa kubalulekile.

I-AutoMotive:

Isetyenziswe kwimveliso yemoto kwaye ilungiswe ekufumaneni izinto ezahlukeneyo, kubandakanya iinxalenye zenjini, iinkqubo zokuphelisa, kunye nezinto ze-chassis.

Oomatshini kunye nemveliso yezixhobo:

Isetyenziswe kwiNdibano yoomatshini kunye nezixhobo, ukubonelela ngonxibelelwano olukhuselekileyo phakathi kweenxalenye ezahlukeneyo.

Umbane kunye ne-elektroniki:

I-Hex Enuts isetyenziswa kwiNdibano yeeNdawo zoMbane, ukulawula iikhanethi, kunye nezinye izixhobo ze-elektroniki.

Izicelo zaselwandle:

I-Stainess Steel Hex Pouts yi-corrosion-enganyangekiyo kwaye ifumane ukusetyenziswa kolwakhiwo lwesikhephe kwaye kulungiswa kwiindawo zaselwandle.

Iiprojekthi zamandla ahlaziyiweyo:

Isetyenziswe ekwakhiweni kweenjini zomoya, izakhiwo zephaneli zeSolar, kunye nezinye iziseko zophuhliso ezihlaziyiweyo.

| Ukuthintela Ubungakanani | Isiseko esikhulu sentambo | Ububanzi beeflethi, f | Ububanzi beekona | Ubukhulu, h | Ukuphelisa umphezulu ukuya kuqhuba i-his, fim | ||||||

| Isikwere, g | Hex, g1 | ||||||||||

| Isiseko | Imiz. | UMax. | Imiz. | UMax. | Imiz. | UMax. | Imiz. | UMax. | |||

| 0 | I-0.060 | 5/32 | I-0.150 | I-0.156 | I-0.206 | I-0.221 | I-0.171 | I-0.180 | I-0.043 | I-0.050 | 0.005 |

| 1 | 0.073 | 5/32 | I-0.150 | I-0.156 | I-0.206 | I-0.221 | I-0.171 | I-0.180 | I-0.043 | I-0.050 | 0.005 |

| 2 | I-0.086 | 3/16 | I-0.180 | I-0.188 | I-0.247 | I-0.265 | I-0.205 | I-0.217 | 0.057 | I-0.066 | 0.006 |

| 3 | I-0.099 | 3/16 | I-0.180 | I-0.188 | I-0.247 | I-0.265 | I-0.205 | I-0.217 | 0.057 | I-0.066 | 0.006 |

| 4 | I-0.112 | 1/4 | I-0.241 | I-0.250 | 0.331 | 0.354 | I-0.275 | I-0.289 | I-0.087 | 0.098 | I-0.009 |

| 5 | I-0.125 | 5/16 | I-0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | I-0.102 | I-0.114 | I-0.011 |

| 6 | I-0.138 | 5/16 | I-0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | I-0.102 | I-0.114 | I-0.011 |

| 8 | I-0.164 | 11/32 | 0.332 | 0.344 | 0.456 | I-0.486 | I-0.378 | 0.397 | I-0.117 | I-0.130 | I-0.012 |

| 10 | I-0.190 | 3/8 | 0.362 | I-0.375 | 0.497 | I-0.530 | I-0.413 | I-0.433 | I-0.117 | I-0.130 | I-0.013 |

| 12 | I-0.216 | 7/16 | I-0.423 | I-0.438 | I-0.581 | 0.691 | 0.482 | I-0.505 | I-0.148 | I-0.161 | I-0.015 |

| 1/4 | I-0.250 | 7/16 | I-0.423 | I-0.438 | I-0.581 | 0.691 | 0.482 | I-0.505 | I-0.178 | I-0.193 | I-0.015 |

| 5/16 | 0.312 | I-9/16 | I-0.545 | I-0.562 | 0.748 | 0.795 | 0.621 | I-0.650 | I-0.208 | I-0.225 | I-0.020 |

| 3/8 | I-0.375 | 5/8 | I-0.607 | 0.625 | 0.833 | 0.884 | 0.692 | 0.722 | I-0.239 | I-0.257 | 0.021 |