Izikrelemnqa oziphetheyo

Umsila we-screw off-few ikwimo yomsila we-drill okanye umsila owahlukileyo. Akukho ntlawulo ye-auxiling iyafuneka. Ingakhutshiwe ngokuthe ngqo, icofe, kwaye iqiniswe kwisenzo okanye impahla yesiseko, esongela ixesha lokwakha. Ziqhelekile ekwakhiweni, ukuvelisa, kunye neeprojekthi ze-DY.

-

I-Stainess Steeles Strelling ScrellIinkcukachaItheyibhile yobukhulu

I-screen yentsimbi engenasinyithi yentsimbi yentsimbi yentsimbi yenzekile izikrelemnqa ezinokukrwela imingxunya kwizinto zentsimbi zofakelo ngaphandle kokuthatha izinto zangaphambili. Ezi krifu zihlala zenziwa ngentsimbi engenasibala, zinamandla aphezulu kunye nokunganyangeki, kwaye zilungele ukufakelwa okukhawulezileyo kwiipleyiti zentsimbi ezingenasitali. I-Stainess Steeling Driling Screlling isetyenziswa ngokubanzi kwimfuno yokufakelwa ngokukhawuleza kufakelo kunye neemfuno zoqhagamshelo oluphezulu, ezinje ngokulungiswa kwentsimbi, kunye nendibano yoomatshini.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 dk UMax = ubukhulu becala 5.5 6.8 7.5 8.1 9.5 10.8 12.4 imiz 5.2 6.44 7.14 7.74 9.14 10.37 11.97 k ≈ 1.7 2.1 2.3 2.5 3 3.4 3.8 r max 1.1 1.4 1.5 1.6 1.9 2.1 2.4 I-Soket No. 1 2 2 2 2 3 3 M1 3 4.2 4.6 4.7 5.1 6.8 7.1 M2 2.8 4 4.2 4.4 5 6.3 7 dp max 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-Stainess yentsimbi ejikelezayoIinkcukachaItheyibhile yobukhulu

I-Stainess yentsimbi ejikeleze i-screelling crow luhlobo lwesikhafu ngamandla aphezulu, ukumelana nokucoca. I-I yonakala uyilo, elinokubhabha ngokuthe ngqo kwiinkuni kunye nentsimbi ngaphandle kokuqhuba kwangaphambili, kwaye ineengenelo zofakelo olulula kunye nesantya esikhawulezayo. Kwangelo xesha, isikhafu sokugqobhoza kwentsimbi engenalula akukho lula ukungcungcutheka, sinokungaxhathisi kakuhle, kunye nobomi benkonzo ende. Ukongeza, uyilo lwentloko ejikelezayo luphucula ukusebenza ngokuqinileyo, kunciphisa ithuba loxinzelelo lomphezulu, kwaye lungalukhusela ngcono umphezulu wento. Ke ngoko, i-Stainion yentsimbi ye-Stal-Driveling Screlling isetyenziswa ngokubanzi ekwakhiweni, ukuvelisa ifanitshala, nakwamanye amasimi.

Ubungakanani bentambo St2.9 St3.5 St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.4 1.6 1.8 1.8 dk max 5.6 7 8 9.5 11 12 imiz 5.3 6.64 7.64 9.14 10.57 11.57 k max 2.4 2.6 3.1 3.7 4 4.6 imiz 2.15 2.35 2.8 3.4 3.7 4.3 r imiz I-0,1 I-0,1 I-0.2 I-0.2 I-0.25 I-0.25 R ≈ 5 6 6.5 8 9 10 dp 2.3 2.8 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 I-Soket No. 1 2 2 2 3 3 M1 3 3.9 4.4 4.9 6.4 6.9 M2 3 4 4.4 4.8 6.2 6.8 -

I-Stainess Stous TrussIinkcukachaItheyibhile yobukhulu

I-screen ye-Stain ye-Stees ye-Stoss Uyilo lweNtloko yeTruss ibonelela ngendawo enkulu yomphezulu wokuphucula ukubamba kunye namandla anyukayo, kuyenza ukhetho olubalaseleyo lweeprojekthi ezinzima.

Ubungakanani bentambo St3.5 (St3.9) St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.3 1.3 1.4 1.6 1.8 1.8 dk max 6.9 7.5 8.2 9.5 10.8 12.5 imiz 6.54 7.14 7.84 9.14 10.37 12.07 k max 2.6 2.8 3.05 3.55 3.95 4.55 imiz 2.35 2.55 2.75 3.25 3.65 4.25 r max 0.5 0.5 0.6 0.7 0.8 I-0.9 R ≈ 5.4 5.8 6.2 7.2 8.2 9.5 I-Soket No. 2 2 2 2 3 3 M1 ≈ 4.2 4.4 4.6 5 6.5 7.1 M2 ≈ 3.9 4.1 4.3 4.7 6.2 6.7 dp max 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-pillip yentsimbi engenasitayile esiyintlokoIinkcukachaItheyibhile yobukhulu

Yenziwe kwintsimbi ephakathi ephakathi, ezi khokhwe zinika ukunganyangeki okukhethekileyo, okubenza balungele ukusetyenziswa kwiindawo ezifuna izinto ezinjengezicelo zangaphandle, zaselwandle, kunye nezixhobo zeshishini. Uyilo lwentloko ye-couggnnink ivumela indawo yokugungxula phezu kofakelo, ukuphucula i-aesthetics kunye nokunciphisa umngcipheko wokuthintela okanye ukuthintelwa. Eli nqaku liyenzela ukhetho oluhle lweeprojekthi apho kubonakala khona kunye nokusebenza kubaluleke kakhulu.

Abafakeli be-Aya bazibophelele ekuboneleleni ngezisombululo ezisebenza kakhulu ezihlangabezana nemigangatho esemgangathweni. Enolwazi lokwakha, ukusebenzelana nemizi, okanye izicelo zemizi-mveliso, ezi zinxibo zokuzixakekisa zinika ibhalansi efanelekileyo yamandla, ukusebenza ngokukuko, kunye neziphumo zenqanaba lobugcisa.

Ubungakanani bentambo St2.9 St3.5 St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.4 1.6 1.8 1.8 dk max 5.5 7.3 8.4 9.3 10.3 11.3 imiz 5.2 6.9 8 8.9 9.9 10.9 k max 1.7 2.35 2.6 2.8 3 3.15 r max 1.2 1.4 1.6 2 2.2 2.4 I-Soket No. 1 2 2 2 3 3 M1 3.2 4.4 4.6 5.2 6.6 6.8 M2 3.2 4.3 4.6 5.1 6.5 6.8 dp 2.3 2.8 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-Stainess yensimbi yeThengiIinkcukachaItheyibhile yobukhulu

I-Aya yofakelo lwe-Aya i-Treads yeThengi yeThengi yeNtloko yeThengi yeNtloko ye-Scelling i-Scells ikwizisombululo ezisemgangathweni eziphakathi zenzelwe ukuqina, ukusebenza kakuhle kunye nokhuseleko. Ezi khokhwe zidibanisa izibonelelo zengcebiso yokuziqhelanisa nentloko yentengo, zinika isiphelo esingenamthungo ngelixa sisusa isidingo sokuntywila kwangaphambili.

Ngomsonto obukhali, ezi zikrikhi zibonelela ngamandla amakhulu okugcina, ukunciphisa ukukhulula ixesha elingaphezulu. Sinokubonelela ngobukhulu obuhlukeneyo kunye neenkcazo, ukuqinisekisa ukuhambelana nezicelo ezahlukeneyo njengophahla, ukuthutha, ukubekwa, kunye noMatshini.

Ubungakanani bentambo St2.9 St3.5 St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.4 1.6 1.8 1.8 dk max 5.5 7.3 8.4 9.3 10.3 11.3 imiz 5.2 6.9 8 8.9 9.9 10.9 k max 1.7 2.35 2.6 2.8 3 3.15 r max 1.2 1.4 1.6 2 2.2 2.4 I-Soket No. 1 2 2 2 3 3 M1 3.2 4.4 4.6 5.2 6.6 6.8 M2 3.2 4.3 4.6 5.1 6.5 6.8 dp 2.3 2.8 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-Stailling Pillips ye-Phillips ye-Drilling DrillIinkcukachaItheyibhile yobukhulu

I-Stainis Steele Steeling Phillips I-Phillips Screet Screws, ngamanye amaxesha ibizwa ngokuba yi-tek screws, zenzelwe zombini zizodwa kwaye zicofe umngxunya ngentsimbi yomsebenzi omnye. I-pillips yokuthambisa iPhillips PAN.3 ukuya kwi-ST6.3, kunye ne-trread ukusuka kwi-9.50mm ukuya kwi-50.00mm. Zonke ii-Aya zonke ze-aya zokuntywila iPhillips PAN PIN zenziwe ukusuka kwintsimbi ephakathi ye-Staight, kwaye ihambelana nemigangatho ye-diye okanye i-ASE. Izinto ezongeziweyo zinokwenziwa zifumaneke ngesicelo, nceda uqhagamshelane neqela lethu lentengiso ngeenkcukacha.

Ubungakanani bentambo St2.9 St3.5 St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.4 1.6 1.8 1.8 dk max 5.6 7 8 9.5 11 12 imiz 5.3 6.64 7.64 9.14 10.57 11.57 k max 2.4 2.6 3.1 3.7 4 4.6 imiz 2.15 2.35 2.8 3.4 3.7 4.3 r imiz I-0,1 I-0,1 I-0.2 I-0.2 I-0.25 I-0.25 R ≈ 5 6 6.5 8 9 10 dp 2.3 2.8 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 I-Soket No. 1 2 2 2 3 3 M1 3 3.9 4.4 4.9 6.4 6.9 M2 3 4 4.4 4.8 6.2 6.8 -

I-Stainess Steel Can CellsIinkcukachaItheyibhile yobukhulu

I-Aya i-Aya ayinambopheli ye-pil-pil-perling ye-parling zenziwa kusetyenziswa intsimbi ephakathi engapheliyo, ukuqinisekisa ukumelana ngokugqwesileyo kumhlwa-rusi, ukohlwaya, kunye neemeko zemozulu eziqatha. Ezi zikrikhi zilungele indawo yangaphakathi nangaphandle, zibonelela ngokuqina kwexesha elide kunye nokusebenza. Ezi zityholo zokuziqhela kwentsimbi ye-Aya ayinasikhuselo se-pirling ye-carlies ye-medicals ezifuna ukuthembeka, ukonakaliswa kokusebenza nzima kolwakhiwo, iinkqubo zokusebenza, kunye nezicelo ze-DIO.

Ubungakanani bentambo St2.9 St3.5 St4.2 I-ST4.8 I-ST5.5 St6.3 P I-pitch 1.1 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.4 1.6 1.8 1.8 dk max 5.6 7 8 9.5 11 12 imiz 5.3 6.64 7.64 9.14 10.57 11.57 k max 2.4 2.6 3.1 3.7 4 4.6 imiz 2.15 2.35 2.8 3.4 3.7 4.3 r imiz I-0,1 I-0,1 I-0.2 I-0.2 I-0.25 I-0.25 R ≈ 5 6 6.5 8 9 10 dp 2.3 2.8 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 I-Soket No. 1 2 2 2 3 3 M1 3 3.9 4.4 4.9 6.4 6.9 M2 3 4 4.4 4.8 6.2 6.8 -

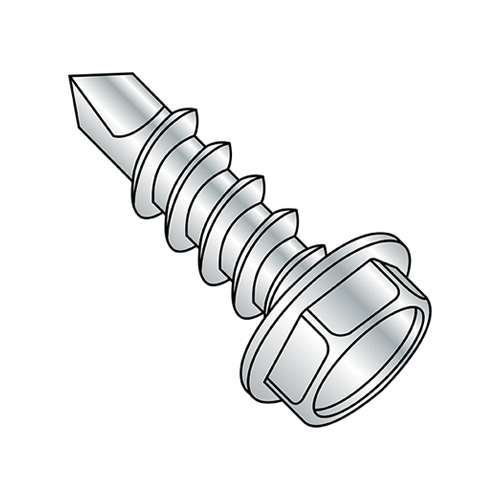

I-Stainess Steeel Hexagon ScrewIinkcukachaItheyibhile yobukhulu

I-Aya hex ye-hex ye-her-felling yentshukumo yenzelwe ukuba yenze umsebenzi oqinisekileyo wokudibanisa izicelo, ekunikezeleni ngokukrokrelwa okuthembekileyo kunye nokusebenza okusebenzayo ngaphandle kwesidingo sokuntywila kwangaphambili.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 (St5.5) St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 c imiz I-0.4 0.6 0.6 0.8 I-0.9 1 1 dc max 6.3 8.3 8.3 8.8 10.5 11 13.5 imiz 5.8 7.6 7.6 8.1 9.8 10 12.2 e imiz 4.28 5.96 5.96 7.59 8.71 8.71 10.95 k max 2.8 3.4 3.4 4.1 4.3 5.4 5.9 imiz 2.5 3 3 3.6 3.8 4.8 5.3 kw imiz 1.3 1.5 1.5 1.8 2.2 2.7 3.1 r max I-0.4 0.5 0.5 0.6 0.7 0.8 I-0.9 s max 4 5.5 5.5 7 8 8 10 imiz 3.82 5.32 5.32 6.78 7.78 7.78 9.78 dp 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-SS HEX CROLD SCROSIinkcukachaItheyibhile yobukhulu

I-Aya ss hex i-head yokuzibulala i-Driling Screws idibanisa intsimbi esemgangathweni ye-hex esebenzisa uyilo lwentloko ye-hex kunye nengcebiso yokuziqhelanisa nefanelekileyo kwizicelo ezahlukeneyo. Nokuba kukwakha izokwakha, ukuyenza, okanye iiprojekthi zokwenza, okanye i-DIY, ezi zikrifu zibonelela ngokuqina, ukulungiselela ukusetyenziswa, kunye nokusebenza okuphezulu.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 (St5.5) St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 c imiz I-0.4 0.6 0.6 0.8 I-0.9 1 1 dc max 6.3 8.3 8.3 8.8 10.5 11 13.5 imiz 5.8 7.6 7.6 8.1 9.8 10 12.2 e imiz 4.28 5.96 5.96 7.59 8.71 8.71 10.95 k max 2.8 3.4 3.4 4.1 4.3 5.4 5.9 imiz 2.5 3 3 3.6 3.8 4.8 5.3 kw imiz 1.3 1.5 1.5 1.8 2.2 2.7 3.1 r max I-0.4 0.5 0.5 0.6 0.7 0.8 I-0.9 s max 4 5.5 5.5 7 8 8 10 imiz 3.82 5.32 5.32 6.78 7.78 7.78 9.78 dp 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-hex yentsimbi yentsimbiIinkcukachaItheyibhile yobukhulu

I-Aya hex ye-hex ye-her-felling yentshukumo yenzelwe ukuba yenze umsebenzi oqinisekileyo wokudibanisa izicelo, ekunikezeleni ngokukrokrelwa okuthembekileyo kunye nokusebenza okusebenzayo ngaphandle kwesidingo sokuntywila kwangaphambili.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 (St5.5) St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 c imiz I-0.4 0.6 0.6 0.8 I-0.9 1 1 dc max 6.3 8.3 8.3 8.8 10.5 11 13.5 imiz 5.8 7.6 7.6 8.1 9.8 10 12.2 e imiz 4.28 5.96 5.96 7.59 8.71 8.71 10.95 k max 2.8 3.4 3.4 4.1 4.3 5.4 5.9 imiz 2.5 3 3 3.6 3.8 4.8 5.3 kw imiz 1.3 1.5 1.5 1.8 2.2 2.7 3.1 r max I-0.4 0.5 0.5 0.6 0.7 0.8 I-0.9 s max 4 5.5 5.5 7 8 8 10 imiz 3.82 5.32 5.32 6.78 7.78 7.78 9.78 dp 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

Hex hesher intloko yentlokoIinkcukachaItheyibhile yobukhulu

I-Aya hex ye-hex ye-her-felling yentshukumo yenzelwe ukuba yenze umsebenzi oqinisekileyo wokudibanisa izicelo, ekunikezeleni ngokukrokrelwa okuthembekileyo kunye nokusebenza okusebenzayo ngaphandle kwesidingo sokuntywila kwangaphambili.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 (St5.5) St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 c imiz I-0.4 0.6 0.6 0.8 I-0.9 1 1 dc max 6.3 8.3 8.3 8.8 10.5 11 13.5 imiz 5.8 7.6 7.6 8.1 9.8 10 12.2 e imiz 4.28 5.96 5.96 7.59 8.71 8.71 10.95 k max 2.8 3.4 3.4 4.1 4.3 5.4 5.9 imiz 2.5 3 3 3.6 3.8 4.8 5.3 kw imiz 1.3 1.5 1.5 1.8 2.2 2.7 3.1 r max I-0.4 0.5 0.5 0.6 0.7 0.8 I-0.9 s max 4 5.5 5.5 7 8 8 10 imiz 3.82 5.32 5.32 6.78 7.78 7.78 9.78 dp 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6 -

I-Stainess I-hex hex i-screlling crillingIinkcukachaItheyibhile yobukhulu

I-Aya Staight Stail Hex Hex I-Scelling Screlling i-screws injini yezicelo zomibini zomishishino nezixhobo zokwakha ngaphandle kwesidingo sokuntywila kwangaphambili. Yenziwe kwintsimbi ephakathi enesibindi, ezi khokhwe zibonelela ngokunganyangeki kakuhle, zenza ukuba zilungele ukusetyenziswa kwiindawo ezahlukeneyo, kubandakanya iinkqubo zangaphandle nezingaselwandle.

Ubungakanani bentambo St2.9 St3.5 (St3.9) St4.2 I-ST4.8 (St5.5) St6.3 P I-pitch 1.1 1.3 1.3 1.4 1.6 1.8 1.8 a max 1.1 1.3 1.3 1.4 1.6 1.8 1.8 c imiz I-0.4 0.6 0.6 0.8 I-0.9 1 1 dc max 6.3 8.3 8.3 8.8 10.5 11 13.5 imiz 5.8 7.6 7.6 8.1 9.8 10 12.2 e imiz 4.28 5.96 5.96 7.59 8.71 8.71 10.95 k max 2.8 3.4 3.4 4.1 4.3 5.4 5.9 imiz 2.5 3 3 3.6 3.8 4.8 5.3 kw imiz 1.3 1.5 1.5 1.8 2.2 2.7 3.1 r max I-0.4 0.5 0.5 0.6 0.7 0.8 I-0.9 s max 4 5.5 5.5 7 8 8 10 imiz 3.82 5.32 5.32 6.78 7.78 7.78 9.78 dp 2.3 2.8 3.1 3.6 4.1 4.8 5.8 Uluhlu lokuqhuba (ubukhulu) 0.7 ~ 1.9 0.7 ~ 2.25 0.7 ~ 2.4 1.75 ~ 3 1.75 ~ 4.4 1.75 ~ 5.25 I-2 ~ 6