Intloko yentloko yentloko

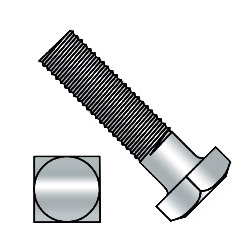

I-Square Helts luhlobo olukhawulezi ngentloko enesikwere eyilelwe ukuba iqiniswe okanye ikhululwe usebenzisa umngxunya. Ezi bolts zaziwa ngohlobo lweNtloko yazo eyahlukileyo, ebonelela ngomphezulu omkhulu we-wrench, ebangela ukuba balungele izicelo apho kufuneka khona i-Tort.

-

I-Stainess Square SkweltsIinkcukachaItheyibhile yobukhulu

Impahla: I-Stainess Sylts yentloko

Izixhobo: zenziwe ngentsimbi engapheliyo engama-304. Babizwa ngokuba yintsimbi engenasibala.

Uhlobo lwentloko: intloko yesikwere.

Ubude: bulinganiselwa phantsi kwentloko.

Uhlobo lomtya Khetha ezi zikrelemnqa ukuba awuyazi i-pitch okanye imisonto kwi-intshi nganye. Imisonto entle neyongezelelweyo-ethe tyaba isondele kakhulu ukuthintela ukukhulula ukukhulula ukuntywila; Imbonakalo yentambo, engcono ukumelana.

Ukunikezelwa: Malunga nesiqingatha samandla amanqanaba aphakathi, ezi zikrikhi zinokusetyenziselwa ukubopha izicelo zokukhanya, njengokufumana iiphaneli zofikelelo lokufikelela. Amanqanaba amakhulu aflethi awenza ukuba abe lula ukubambana nomngxunya kwaye uzigcine ekujikelezisweni kwimingxunya yesikwere.

Umgangatho: isikhafu esidibana ne-ASTE B1.1, i-ASTE B18.2.1, ihambelana nemigangatho yemilinganiselo.Intambo yokukhangela 1/4 5/16 3/8 7/16 1/2 5/8 I-3/4 7/8 1 I-1-1 / 8 I-1-1 / 4 I-1-3 / 8 I-1-1 / 2 d d I-0.25 0.3125 I-0.375 I-0.4375 0.5 0.625 0.75 0.875 1 1.125 1.25 1.375 1.5 PP I-UNC 20 18 16 14 13 11 10 9 8 7 7 6 6 ds max I-0.26 I-0.324 0.388 0.452 I-0.515 0.642 0.768 0.895 1.022 1.149 1.277 1.404 1.531 imiz I-0.237 I-0.298 0.36 I-0.421 0.482 I-0.605 0.729 I-0.852 0.976 1.098 1.223 1.345 1.47 s Ubungakanani beLizwe 3/8 1/2 I-9/16 5/8 I-3/4 15/16 I-1-1 / 8 I-1-5 / 16 I-1-1 / 2 1-11 / 16 I-1-7 / 8 I-2-1 / 16 I-2-1 / 4 max I-0.375 0.5 I-0.562 0.625 0.75 0.938 1.125 1.312 1.5 1.688 1.875 2.062 2.25 imiz 0.362 0.484 0.544 I-0.603 0.725 I-0.906 1.088 1.269 1.45 1.631 1.812 1.994 2.175 e max 0.53 0.707 0.795 0.884 1.061 1.326 1.591 1.856 2.121 2.386 2.652 2.917 3.182 imiz 0.498 I-0.665 0.747 0.828 I-0.995 1.244 1.494 1.742 1.991 2.239 2.489 2.738 2.986 k Ubungakanani beLizwe 11/64 13/64 1/4 I-19/64 21/64 27/64 1/2 I-19/32 21/32 I-3/4 27/32 29/32 1 max I-0.188 I-0.22 I-0.268 0.316 0.348 I-0.444 0.524 0.62 I-0.684 0.78 0.876 I-0.94 1.036 imiz I-0.156 I-0.186 I-0.232 I-0.278 0.308 I-0.4 I-0.476 I-0.568 0.628 0.72 I-0.812 0.872 0.964 r max I-0.03 I-0.03 I-0.03 I-0.03 I-0.03 I-0.06 I-0.06 I-0.06 I-0.09 I-0.09 I-0.09 I-0.09 I-0.09 imiz I-0.01 I-0.01 I-0.01 I-0.01 I-0.01 I-0.02 I-0.02 I-0.02 I-0.03 I-0.03 I-0.03 I-0.03 I-0.03 b L≤6 0.75 0.875 1 1.125 1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 L> 6 1 1.125 1.25 1.375 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5 -

I-Stainess Square Square BlietsIinkcukachaItheyibhile yobukhulu

Impahla: I-Stainess Square Bliets

Izixhobo: zenziwe ngentsimbi engapheliyo engama-304. Babizwa ngokuba yintsimbi engenasibala.

Uhlobo lwentloko: intloko yesikwere.

Ubude: bulinganiselwa phantsi kwentloko.

Uhlobo lomtya Khetha ezi zikrelemnqa ukuba awuyazi i-pitch okanye imisonto kwi-intshi nganye. Imisonto entle neyongezelelweyo-ethe tyaba isondele kakhulu ukuthintela ukukhulula ukukhulula ukuntywila; Imbonakalo yentambo, engcono ukumelana.

Ukunikezelwa: Malunga nesiqingatha samandla amanqanaba aphakathi, ezi zikrikhi zinokusetyenziselwa ukubopha izicelo zokukhanya, njengokufumana iiphaneli zofikelelo lokufikelela. Amanqanaba amakhulu aflethi awenza ukuba abe lula ukubambana nomngxunya kwaye uzigcine ekujikelezisweni kwimingxunya yesikwere.

Umgangatho: isikhafu esidibana ne-ASTE B1.1, i-ASTE B18.2.1, ihambelana nemigangatho yemilinganiselo.Intambo yokukhangela 1/4 5/16 3/8 7/16 1/2 5/8 I-3/4 7/8 1 I-1-1 / 8 I-1-1 / 4 I-1-3 / 8 I-1-1 / 2 d d I-0.25 0.3125 I-0.375 I-0.4375 0.5 0.625 0.75 0.875 1 1.125 1.25 1.375 1.5 PP I-UNC 20 18 16 14 13 11 10 9 8 7 7 6 6 ds max I-0.26 I-0.324 0.388 0.452 I-0.515 0.642 0.768 0.895 1.022 1.149 1.277 1.404 1.531 imiz I-0.237 I-0.298 0.36 I-0.421 0.482 I-0.605 0.729 I-0.852 0.976 1.098 1.223 1.345 1.47 s Ubungakanani beLizwe 3/8 1/2 I-9/16 5/8 I-3/4 15/16 I-1-1 / 8 I-1-5 / 16 I-1-1 / 2 1-11 / 16 I-1-7 / 8 I-2-1 / 16 I-2-1 / 4 max I-0.375 0.5 I-0.562 0.625 0.75 0.938 1.125 1.312 1.5 1.688 1.875 2.062 2.25 imiz 0.362 0.484 0.544 I-0.603 0.725 I-0.906 1.088 1.269 1.45 1.631 1.812 1.994 2.175 e max 0.53 0.707 0.795 0.884 1.061 1.326 1.591 1.856 2.121 2.386 2.652 2.917 3.182 imiz 0.498 I-0.665 0.747 0.828 I-0.995 1.244 1.494 1.742 1.991 2.239 2.489 2.738 2.986 k Ubungakanani beLizwe 11/64 13/64 1/4 I-19/64 21/64 27/64 1/2 I-19/32 21/32 I-3/4 27/32 29/32 1 max I-0.188 I-0.22 I-0.268 0.316 0.348 I-0.444 0.524 0.62 I-0.684 0.78 0.876 I-0.94 1.036 imiz I-0.156 I-0.186 I-0.232 I-0.278 0.308 I-0.4 I-0.476 I-0.568 0.628 0.72 I-0.812 0.872 0.964 r max I-0.03 I-0.03 I-0.03 I-0.03 I-0.03 I-0.06 I-0.06 I-0.06 I-0.09 I-0.09 I-0.09 I-0.09 I-0.09 imiz I-0.01 I-0.01 I-0.01 I-0.01 I-0.01 I-0.02 I-0.02 I-0.02 I-0.03 I-0.03 I-0.03 I-0.03 I-0.03 b L≤6 0.75 0.875 1 1.125 1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 L> 6 1 1.125 1.25 1.375 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5