Iimveliso

Izikrelemnqa ezingaqhelekanga

Ingcaciso yeMveliso

| Igama lemveliso | Izikrelemnqa ezingaqhelekanga |

| Isixhobo | Yenziwe kwintsimbi engama-304 yenqwaba, ezi zikrikhi zinengxaki yokunganyangeki ibe nemichiza kwaye inokuba ngumazibuthe onobulali. Babizwa ngokuba yintsimbi engenasibala. |

| Uhlobo lwentloko | Intloko |

| Uhlobo lokuqhuba | Ukuphumla |

| Ubude | Ilinganiswe entloko |

| Isicelo | Izikrelem ze-chipboard zilungele imisebenzi yokwakha ukukhanya, njengokufaka iiphaneli, ukujikeleza udonga, kunye nezinye izinto ezomeleleyo nezihlala gwenxa ziyafuneka, kwaye zisetyenziswa ngokubanzi kwindibano yeChipboard kunye ne-MDF (i-firning fibberboard fiberboard). |

| Umgangatho | Izikrelemnqa ezidibana ne-Asme okanye i-Din 7505 (a) ngemigangatho yobungakanani. |

Isibonelelo seStaipbonking Chipboard Screws

1. Ukunganyangeki kwe-ucrosion: eyenziwe ngentsimbi engenasimo, ezi zikhafu zixhaphake kakhulu kwi-rust kunye nokunyanzelwa, zibenza balungele ukusetyenziswa kwemeko okanye kwiimeko ezinzima.

2. Isibongozo esihle: Uyilo lwe-Couggnnink luvumela intloko yesikhafu ukuze ilingane okanye ngaphantsi komphezulu weenkuni, zibonelela ngokugqitywa okucocekileyo kunye nokugqiba ngokucocekileyo. Oku kubaluleke kakhulu kwimiphezulu ebonakalayo apho inkangeleko entle ifunwa khona.

3. Amandla kunye nokuqhekeka: intsimbi engenasimo ibonelela ngamandla agqwesileyo kunye nokuqina, ukuqinisekisa ukuba izikrikhi zibambe ixesha elingakumbi ngaphandle kokuphazamisa okanye ukophula phantsi koxinzelelo.

I-4. Ukuhambelana ne-chipboard: Ezi zikrikhi ziyilelwe ngokukodwa ukuba zisetyenziswe nge-chipboard, zibonelela ngesisombululo esikhuselekileyo nesinokuthenjwa esithintela izinto.

I-5. Ukukhululeka kokufakwa: Uyilo lwezikrelem zivumela ukufakelwa ngokulula nangokufanelekileyo, ukunciphisa umzamo ofunekayo ukukhusela indawo.

I-6. Ukusebenza kwexesha elide: Ngenxa yokunganyangeki kwabo kunye nokuqina kwabo, i-staining torch chipboard crews ibonelela ngokusebenza kwexesha elide, ukunciphisa isidingo solondolozo okanye ukutshintshwa.

7. UQHELEKO: Nangona benzelwe i-chipboard, ezi zikrikhi zinokusetyenziswa nezinye iintlobo zenkuni kunye nezixhobo, zisenza zibe ziintsusa zezicelo ezahlukeneyo.

Ukusetyenziswa kwezikrelem ezingenasitali

●Imveliso yefanitshala:I-Chipboard Screws ibalulekile ekuhlanganiseni iindlela ezahlukeneyo zefanitshala, kubandakanya neetafile, izitulo, iikhabhathi, kunye neeheshel. Amandla abo okukhusela ngokukhuselekileyo ajoyine iiphaneli ze-Chipboard ukuqinisekisa ukuthembeka kwempahla yefanitshala.

●ICAB:Kwiikhabhathi zekhitshi kunye neekhabhathi zegumbi lokuhlambela, i-SS Chipboard Screws Dlala indima yokudibanisa iibhokisi zeKhabhinethi kunye nokuncamathisela izixhobo ezifana ne-hinges slide kunye nezilayidi zekhasisi.

●Ufakelo lomgangatho:Kumgangatho we-laminate kunye nenjineli ye-hipboard ye-chipboard screws zisetyenziselwa ukukhusela ukuphendulwa, ukudala isiseko esizinzileyo sabayali bokugqibela.

●Iiprojekthi ze-DIY:I-Chipboard Screws lukhetho lokuqala kubantu abanothando abasebenza kwiiprojekthi kubandakanya i-chipboard okanye i-50 yebhodi, iyunithi yokugcina, okanye imisebenzi yokugcina.

●Izicelo zangaphandle:Ezinye izikrelem ze-chipboard ziphathwa ngeengubo ezinganyangekiyo ze-corrosion ezibenza balungele iinkqubo zangaphandle. Banokusetyenziselwa ukudibanisa ifanitshala yangaphandle, izakhiwo zegadi, okanye iidesika zokhuni.

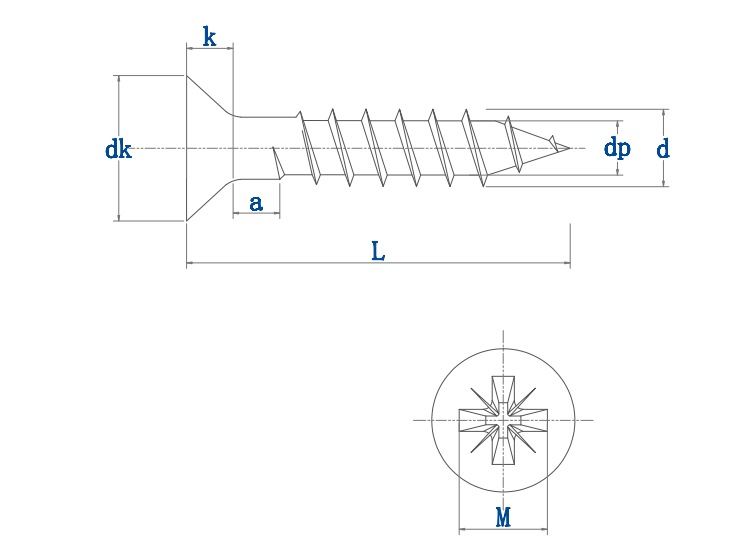

| Ngeenyawo zentambo ezimangalisayo | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | ||

| d | max | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | |

| imiz | 2.25 | 2.75 | 3.2 | 3.7 | 4.2 | 4.7 | 5.7 | ||

| P | I-pitch (± 10%) | 1.1 | 1.35 | 1.6 | 1.8 | 2 | 2.2 | 2.6 | |

| a | max | 2.1 | 2.35 | 2.6 | 2.8 | 3 | 3.2 | 3.6 | |

| dk | UMax = ubukhulu becala | 5 | 6 | 7 | 8 | 9 | 10 | 12 | |

| imiz | 4.7 | 5.7 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | ||

| k | 1.4 | 1.8 | 2 | 2.35 | 2.55 | 2.85 | 3.35 | ||

| dp | UMax = ubukhulu becala | 1.5 | 1.9 | 2.15 | 2.5 | 2.7 | 3 | 3.7 | |

| imiz | 1.1 | 1.5 | 1.67 | 2.02 | 2.22 | 2.52 | 3.22 | ||

| I-Soket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | ||

| M | 2.51 | 3 | 4 | 4.4 | 4.8 | 5.3 | 6.6 | ||