Iimveliso

I-Stainess Steel Can Cells

Ingcaciso yeMveliso

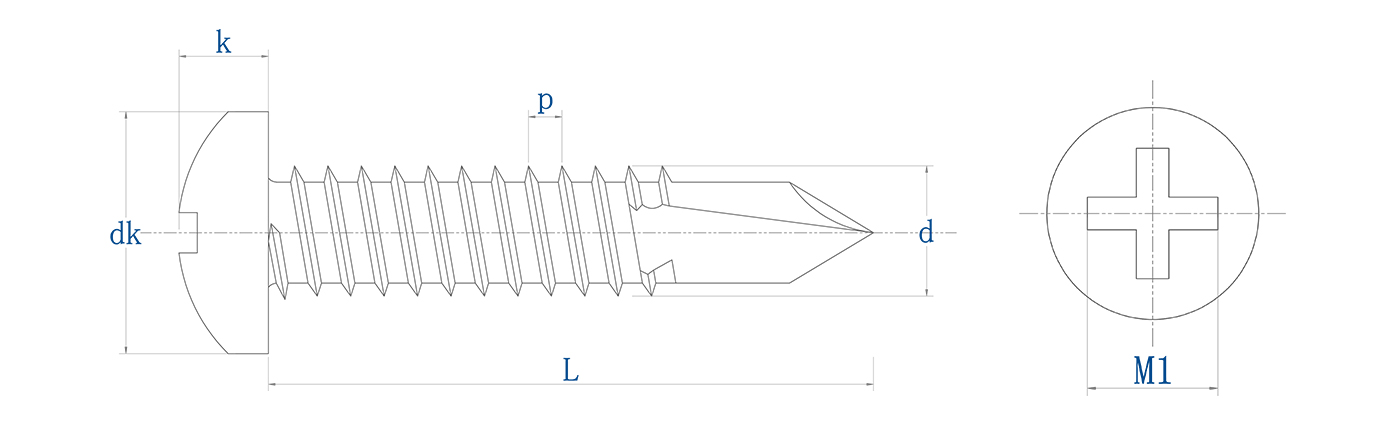

| Igama lemveliso | I-Stailling Pillips ye-Phillips ye-Drilling Drill |

| Isixhobo | Yenziwe kwintsimbi engenasimo, ezi zikrikhi zinengxaki yokungaxhathisi beekhemikhali kwaye zinokuba ngumanyatha |

| Uhlobo lwentloko | Intloko ye-pan |

| Ubude | Ilinganiswe phantsi kwentloko |

| Isicelo | Isikrelemnqa sokuzixakekisa sinendawo ye-drill bit esusa imisebenzi eyahlukileyo yokuqhuba kunye nokufakwa koqoqosho ngakumbi. Inqaku le-Drill livumela ezi scrill i-screll ifakwe kwizixhobo ezisisiseko zentsimbi ukuya kuthi ga kwi-1/2 "i-screbles ye-terming ziyafumaneka ngeendlela ze-screw diamester # 6 thru 5 / 16 "-18. |

| Umgangatho | Izikrelemnqa ezidibana ne-ASME B18.6.3 okanye i-7504 (m) ngemigangatho yemilinganiselo |

IINGXAKI ZOKUXELISA I-STAGE YENKCUBEKO YOKUGQIBELA

I-1. I-pan ye-pan ye-pan ye-parll ibonisa intloko ejikelezileyo, eneprofayili elihlala ngaphezulu komphezulu wezinto ezibonakalayo. Lo uyilo lwentloko lusasaza uxinzelelo ngokulinganayo, ukuthintela ukonakaliswa kwezinto ezithambileyo ezinjengeenkuni okanye ngeplastiki ngelixa unikezela inkangeleko emnyama, egqityiweyo.

2. Ubume bentsimbi engenasibala bunika ukunganyangeki kwentsimbi ephezulu, ukwenza ezi zikrikhi zilungele indawo yangaphandle nezaselwandle.

3. Ngeempawu zokuziqhelanisa nokuziqhelanisa, ufakelo ngokukhawuleza, ukunciphisa ixesha lezabasebenzi kunye neendleko.

4. Ulwakhiwo lwentsimbi engenasitali luqinisekisa amandla aphezulu kunye nokuqina, nangona kufuneka izicelo.

5. Isiphelo sentsimbi esingenangqondo sinikezela ngembonakalo yobungcali kunye nokucoceka, ngakumbi ekufakeni ukufakelwa.

I-6. Izikrikhi zixhotyiswe ngemisonto ebukhali, echanekileyo yenjineli enqumama amanye amaqathango, ezinjengesinyithi yephepha, iinkuni, kunye nemfuno yomngxunya othambileyo. Intambo yenzelwe ukuba ibutyebi obugudileyo kunye namandla amakhulu abamba.

I-7. Ziyafumaneka kwi-metric kunye ne-MAPRIC, ukuqinisekisa ukuhambelana noluhlu olubanzi lweeprojekthi.

8. I-Aya intsimbi engenasitayile ihlangabezana nemigangatho yehlabathi yomgangatho kunye nokusebenza, ukuqinisekisa ukusebenza ngokuthembekileyo kwizicelo ezibalulekileyo.

Ukusetyenziswa kwe-Stainess ye-Staiel ye-Stain

• Ulwakhiwo: Ezi zikrikhi zisetyenziswa ngokubanzi kwi-iron yensimbi, ivala, kunye nezinye iinkqubo zesakhiwo.

• Uphahla kunye nokuvala: Ilungele intsimbi-to-inyibilikisi ephahlani, kunye nokuncamathisela iiphaneli.

I-HVAC: isetyenziswe kufakelo lwe-fucct kunye namanye amalungu e-HVAC.

Ukufakwa kombane: Ifezekile ekufumaneni iibhokisi zombane kunye neephaneli ukuya kwizakhiwo zentsimbi.

| Ubungakanani bentambo | St2.9 | St3.5 | St4.2 | I-ST4.8 | I-ST5.5 | St6.3 | ||

| P | I-pitch | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| a | max | 1.1 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| dk | max | 5.6 | 7 | 8 | 9.5 | 11 | 12 | |

| imiz | 5.3 | 6.64 | 7.64 | 9.14 | 10.57 | 11.57 | ||

| k | max | 2.4 | 2.6 | 3.1 | 3.7 | 4 | 4.6 | |

| imiz | 2.15 | 2.35 | 2.8 | 3.4 | 3.7 | 4.3 | ||

| r | imiz | I-0,1 | I-0,1 | I-0.2 | I-0.2 | I-0.25 | I-0.25 | |

| R | ≈ | 5 | 6 | 6.5 | 8 | 9 | 10 | |

| dp | 2.3 | 2.8 | 3.6 | 4.1 | 4.8 | 5.8 | ||

| Uluhlu lokuqhuba (ubukhulu) | 0.7 ~ 1.9 | 0.7 ~ 2.25 | 1.75 ~ 3 | 1.75 ~ 4.4 | 1.75 ~ 5.25 | I-2 ~ 6 | ||

| I-Soket No. | 1 | 2 | 2 | 2 | 3 | 3 | ||

| M1 | 3 | 3.9 | 4.4 | 4.9 | 6.4 | 6.9 | ||

| M2 | 3 | 4 | 4.4 | 4.8 | 6.2 | 6.8 | ||