Iimveliso

I-Stainess Steeles Strelling Screll

Ingcaciso yeMveliso

| Igama lemveliso | I-Stainess Steeles Strelling Screll |

| Isixhobo | Yenziwe kwintsimbi engenasimo, ezi zikrikhi zinengxaki yokungaxhathisi kunye nokuba ngu-manetic. |

| Uhlobo lwentloko | Intloko |

| Ubude | Ilinganiswe ukusuka phezulu kwentloko |

| Isicelo | Ayisiyo isetyenziselwa i-Aluminium yensimbi yesinyithi. Zonke zityhafile phantsi kwentloko ukuze zisetyenziswe kwimingxunya yokuhlinqe. Izikrelemnqa zingena kwi-0.025 "kunye ne-ticner sheet |

| Umgangatho | Izikati ezidibana ne-Asme B18.6.3 okanye din 7504-P enemigangatho yobungakanani |

IINGXAKI ZOKUXELISA I-SCRE YOBUCHULE BOKUGQIBELA

I-1. Intshukumo ephezulu yokucoca: Intsimbi engenasitali ixhaphakile kakhulu kwi-rust kunye ne-corrosion, ethetha ukuba ezi zikrikhi ziya kuhlala ixesha elide kwaye zifuna ulondolozo oluncinci.

2. Amandla aphezulu: Intsimbi engenasitali sisinyithi esomeleleyo, kwaye ezi screlling zensimbi zentsimbi zenzelwe ukuba zingene ngokulula izinto ezinzima ngaphandle kokuqhekeza okanye ukugoba.

3. Kulula ukuzisebenzisa: Ezi zikreyi ziyilelwe ngokukodwa ukuqhuba nokuqhuba kwinsimbi ngaphandle kwemfuneko yokuqhuba kwangaphambili, kubenza babe lula kwaye bakhawuleze basebenzise nayiphi na iprojekthi yentsimbi.

I-4. Ukungahambi kakuhle: Ezi zikreyi zinokusetyenziswa kwizicelo ezahlukeneyo, kubandakanya nophahla lwentsimbi, i-suir, kunye ne-gutters, zisenza ukuba kubekho ukhetho lokwakha.

I-5. I-Beesthetic Isibongozo: I-Sleight I-Staight yentsimbi engenasimo yongeza ukuchukumisa kwale mihla nakweyiphi na iprojekthi, ukwenza ezi khreyiza ukhetho olugqibeleleyo kwabo bafuna ukufezekisa isiphelo esiphezulu, ubungcali.

UKUFAKWA KWESIQINISEKISO SOKUGQIBELA

Isikrelemnqa esingapheliyo sentsimbi yentsimbi sisikrini esisebenzayo, esifanelekileyo nesisebenzayo nesisebenzayo sentsimbi. Ingasetyenziswa ekwenzeni nasekufakweni kolwakhiwo, oomatshini, ii-elektroniki, izithuthi, kunye namanye amashishini. Makhe sihlolisise isicelo esithile se-screen esingenasitayile esingenantambo.

I-1. Intsimbi engenasinyithi esiyintsimbi inokusetyenziswa kumzi-mveliso wokwakha. Kwiindawo zokwakha, abasebenzi kufuneka basebenzise izikrelemnqa ukulungisa iipleyiti, iipleyiti kunye nezinye izinto ezenziwe ngentsimbi, zinokuqhagamshela kwaye ziqhagamshele izixhobo ezahlukeneyo, zixabisa ixesha lokwakha kunye nexabiso ngexesha le Iprojekthi yokwakha.

I-2. I-Stainess Steel Steeling yentsimbi inokusetyenziswa kwimveliso yoomatshini. Inani elikhulu le-screws lihlala lifuneka kwinkqubo yemveliso yezixhobo zoomatshini. I-screen yentsimbi engenasinyithi ineempawu zamandla aphezulu, anti-oxidation, kwaye akukho lula ukukhulula, enokuqinisekisa uzinzo nokhuseleko lwezixhobo zoomatshini.

I-3. Intsimbi engenasinqwazi sentsimbi yentsimbi inokusetyenziswa ekwenzeni izixhobo ze-elektroniki zokuqinisekisa ukuthembeka nokukhuseleka kwezixhobo ze-elektroniki. Kwinkqubo yokuphucula iimoto nayo kufuneka isebenzise inani elikhulu le-screen yentsimbi engenasitayile, ukusetyenziswa kwesi screw kunokuphucula ukwenziwa kwemveliso kunye nomgangatho, ukuqinisekisa ukhuseleko kunye nezixhobo zemoto kunye nezixhobo zemoto.

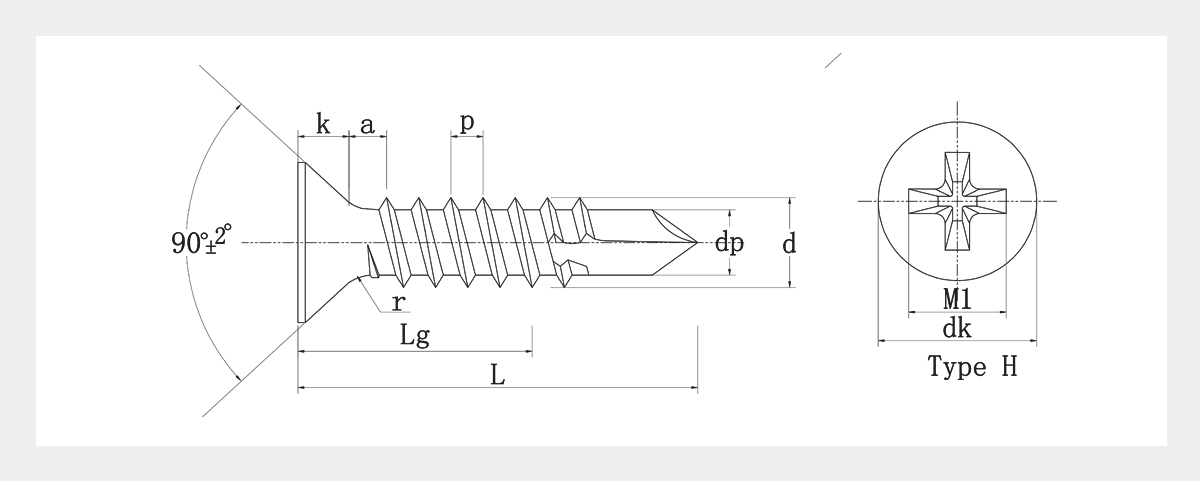

| Ubungakanani bentambo | St2.9 | St3.5 | (St3.9) | St4.2 | I-ST4.8 | I-ST5.5 | St6.3 | ||

| P | I-pitch | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| a | max | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |

| dk | UMax = ubukhulu becala | 5.5 | 6.8 | 7.5 | 8.1 | 9.5 | 10.8 | 12.4 | |

| imiz | 5.2 | 6.44 | 7.14 | 7.74 | 9.14 | 10.37 | 11.97 | ||

| k | ≈ | 1.7 | 2.1 | 2.3 | 2.5 | 3 | 3.4 | 3.8 | |

| r | max | 1.1 | 1.4 | 1.5 | 1.6 | 1.9 | 2.1 | 2.4 | |

| I-Soket No. | 1 | 2 | 2 | 2 | 2 | 3 | 3 | ||

| M1 | 3 | 4.2 | 4.6 | 4.7 | 5.1 | 6.8 | 7.1 | ||

| M2 | 2.8 | 4 | 4.2 | 4.4 | 5 | 6.3 | 7 | ||

| dp | max | 2.3 | 2.8 | 3.1 | 3.6 | 4.1 | 4.8 | 5.8 | |

| Uluhlu lokuqhuba (ubukhulu) | 0.7 ~ 1.9 | 0.7 ~ 2.25 | 0.7 ~ 2.4 | 1.75 ~ 3 | 1.75 ~ 4.4 | 1.75 ~ 5.25 | I-2 ~ 6 | ||